Dec 29: With Angel Rice project successfully completed (though I have some ideas left regarding aging, it won't be a lot of work, I just need to wait for some things I ordered online to arrive), I realized that I still have most of the bag of Angel yeast left; Sure, I've done my best to reseal it, and it's in my fridge, but it's not going to last like that forever; I'm pretty sure it's still viable, but for how long? I better use it soon

I've already made rice alcohol, so this time I'm thinking I'm doing something different; We're going to feed it some unmashed barley, and see how it handles it

There's only one place in Santa Rosa where you can buy barley, it's the Beverage People. I got 50 pounds of 6 row, and they even were so kind to crush it for me. I'll only need 40 for this project, the rest I can use for beer at some point in the future. Buying a whole bag was cheaper, and barley is generally useful

Buckle up, we're going to make some booze

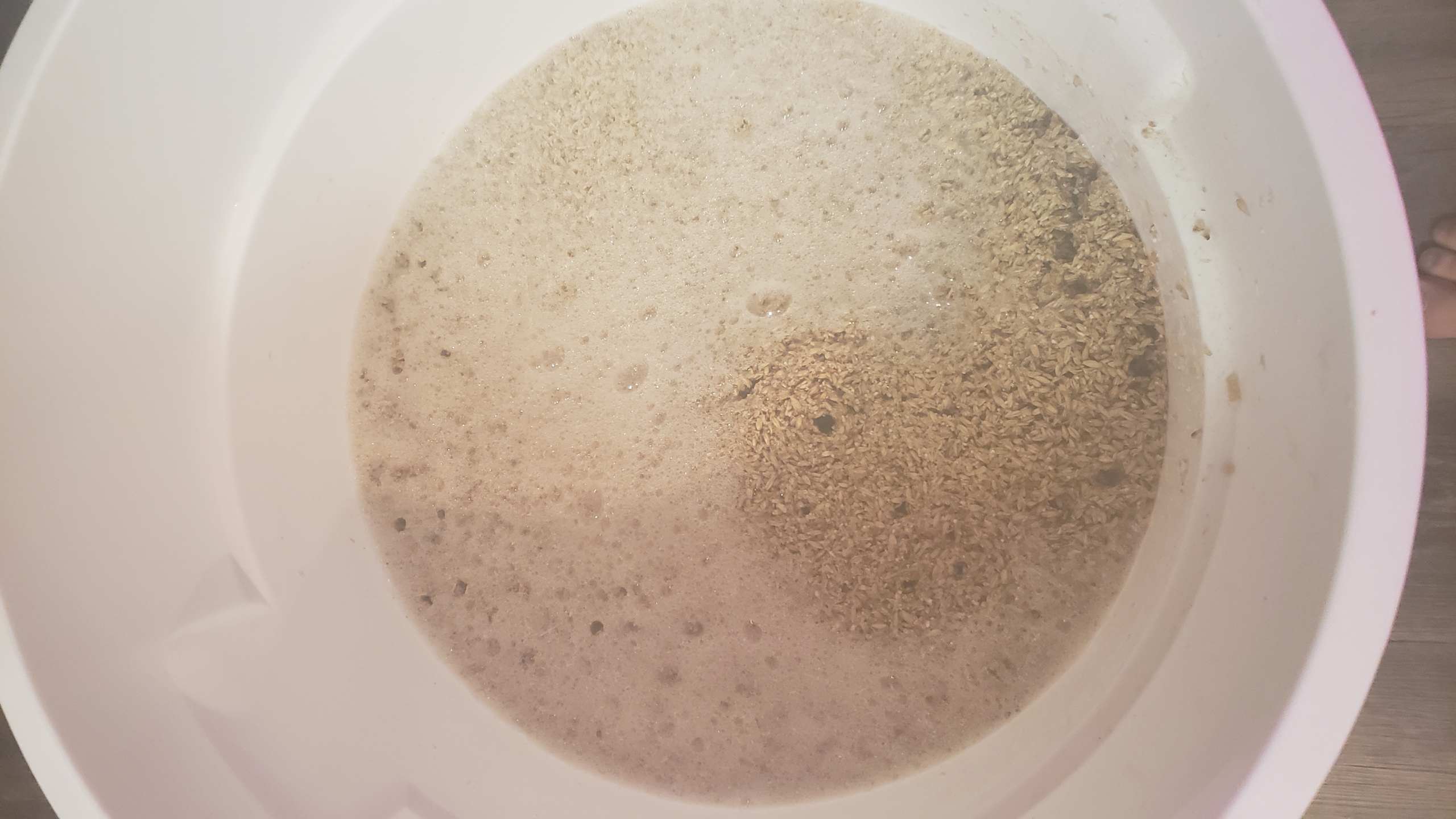

So, 40 pounds are going into the bucket.. That's a lot of barley. 40 pounds of rice took much less space

Then I poured 4 gallons of boiling water into it. With some luck, there will be some pockets with temperature in the starch conversion range, so some of the starches will get broken down. Not that it matters in our case, of course

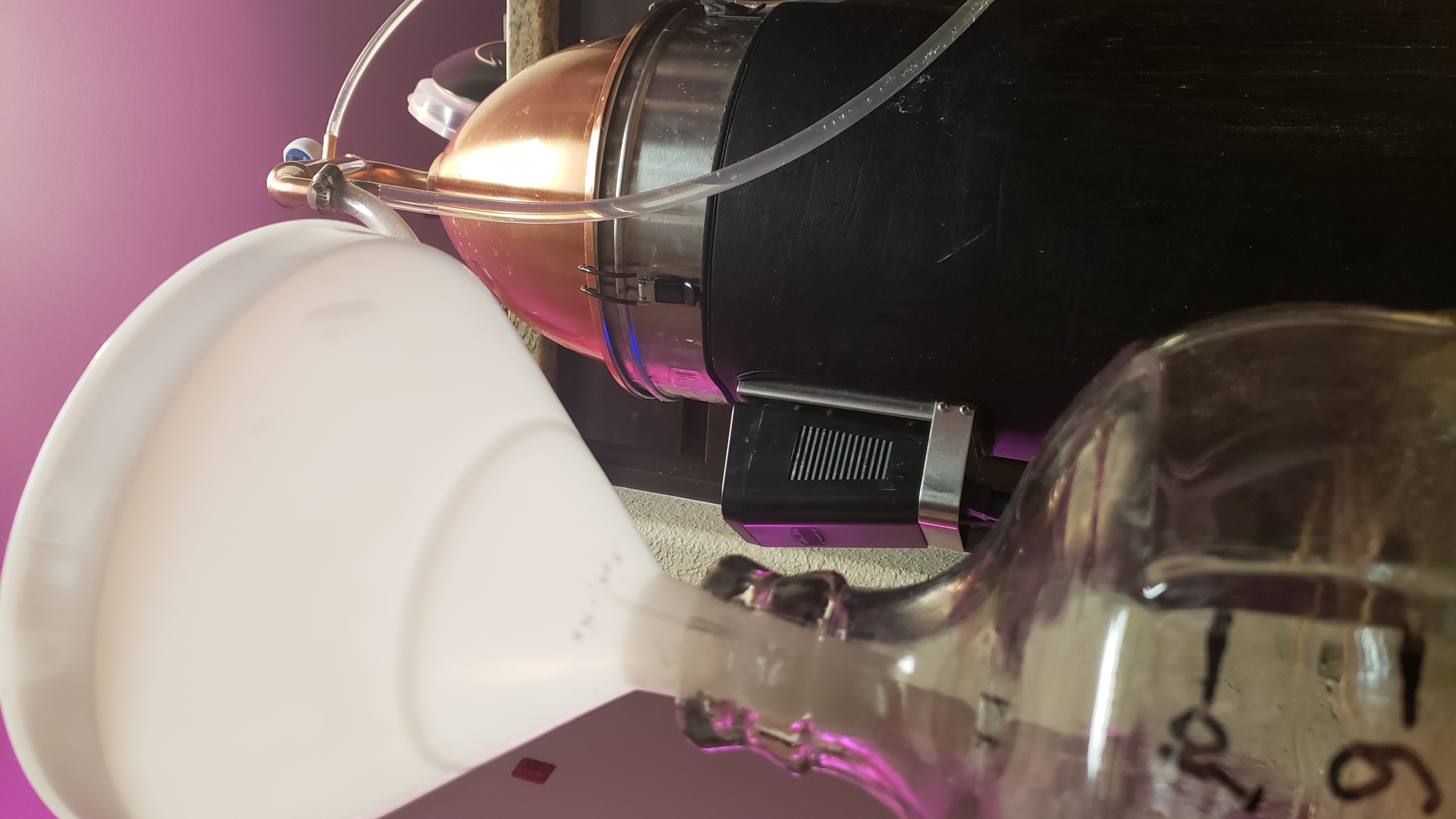

This is barley soaking in hot water

And then, after a little bit of waiting, 8 more gallons of cold water

So, that's 12 gallons total. I'll add 2.5 gallons later, when fermentation calms down a little. Last thing I want is for the foam to overflow

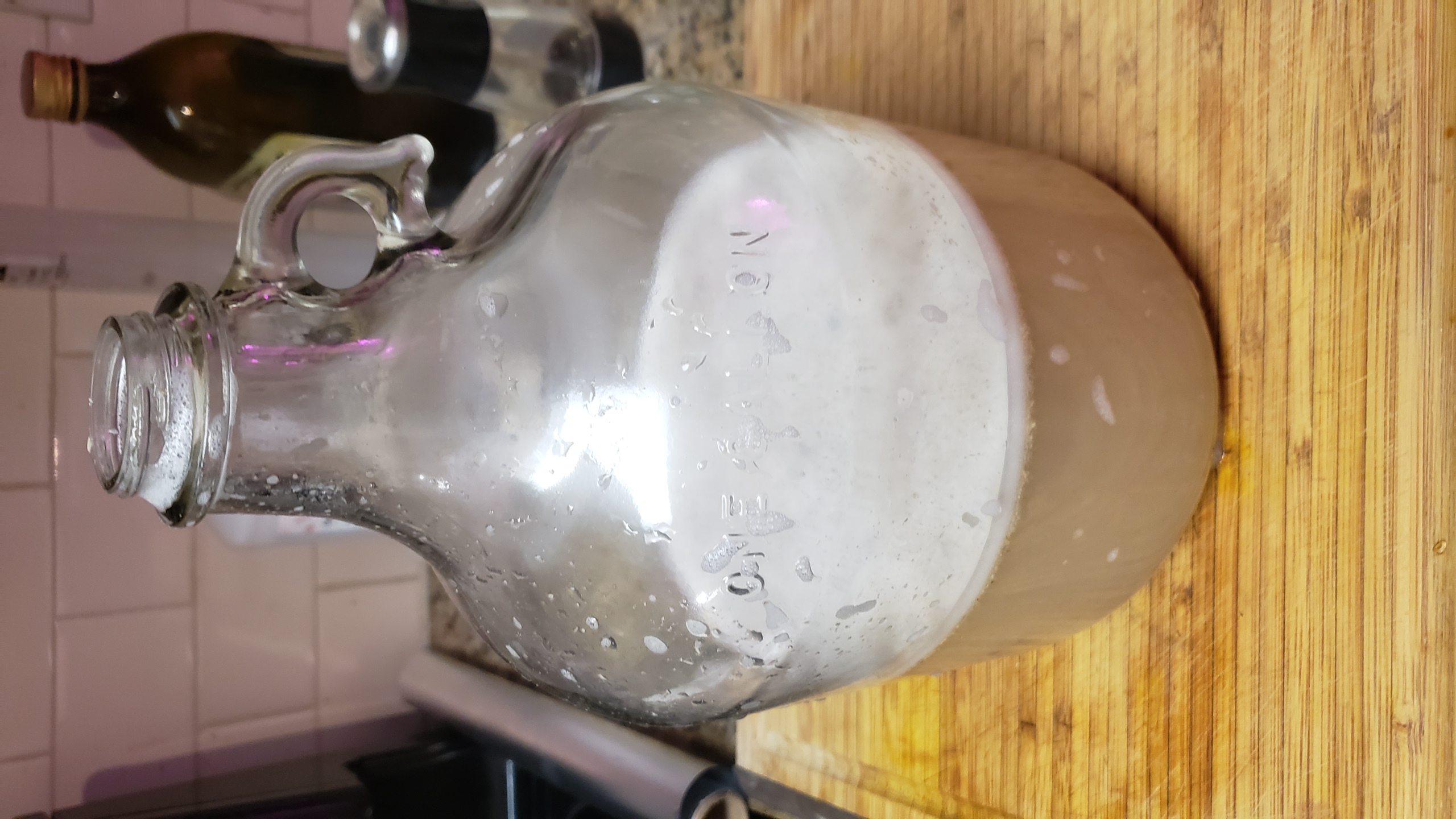

Then, time to scoop up some starch juice and make a starter

So, half an hour later fermentation is going strong in the jar. Not a lot of yeast foam, but I can see the currents inside, and bubbles rising. Everything's in order

Then I remembered that I have no reason to keep the rest of the yeast, and just yeeted it into the fermenter, along with the starter

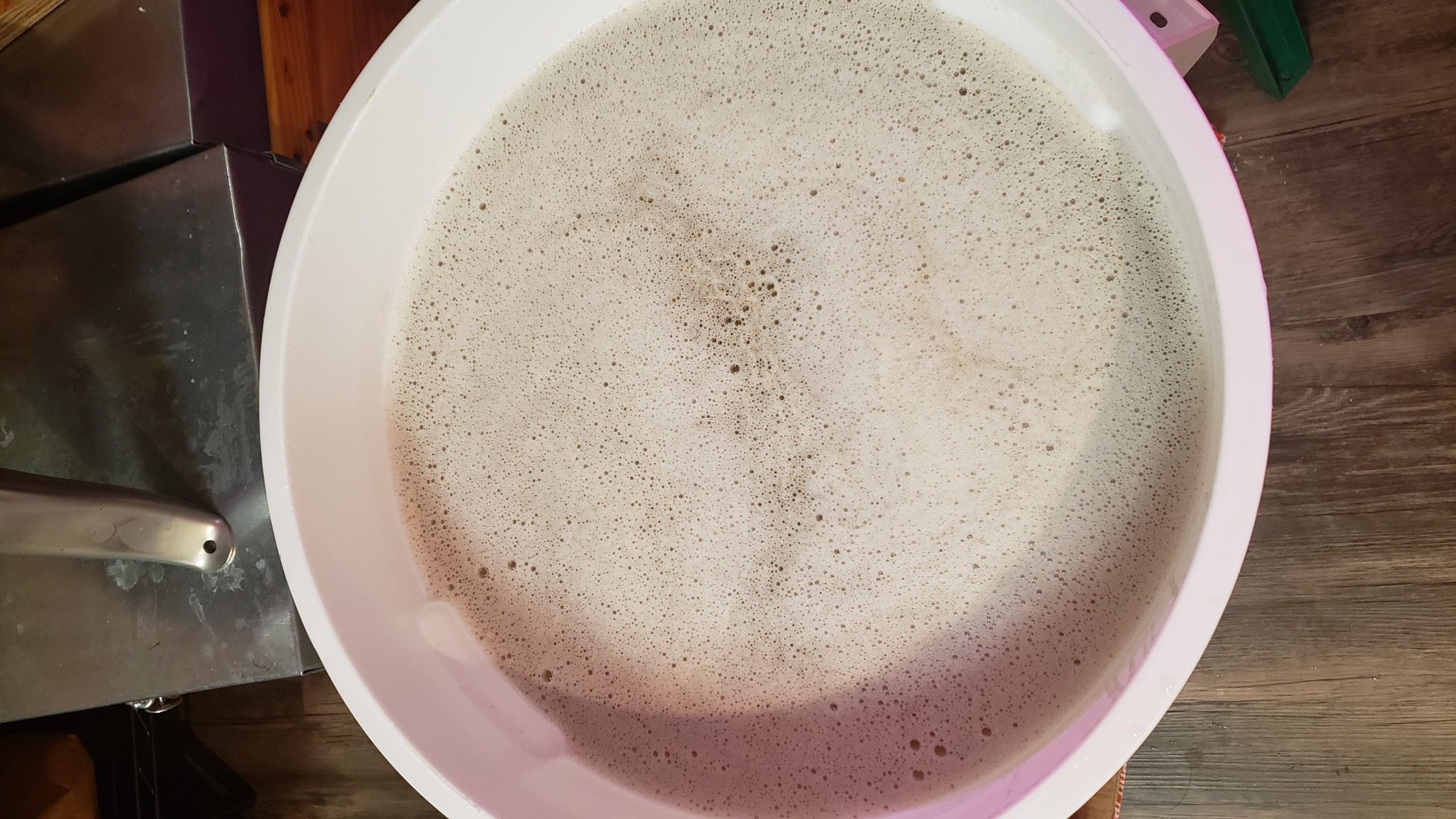

A couple hours later I checked inside the bucket; To my surprise, barley started rising to the top

That's surprising; grain tends to stay at the bottom of the mash while brewing beer; must be something the fungus is doing

I decided to give it a good swirl. There's definitely some fermentation going on, with the liquid slowly bubbling

I mixed it up well, barley seems to stay down for now

I'll keep a close eye on it for the next few days

Dec 30: Fermentation is going strong. Fermenter bucket is warm to touch, and there are some bubbles; Grain keeps rising to the top; does the culture do something to make it lighter? Or do the rising bubbles push it up?

It doesn't look like it will be foaming much, so I added the remaining 2.5 gallons of water into the fermenter. It's a little too full for my taste, but should be good, I think

The smell is changing; yesterday it just smelled like barley. Today the smell is sour, and I think it's becoming a little boozy

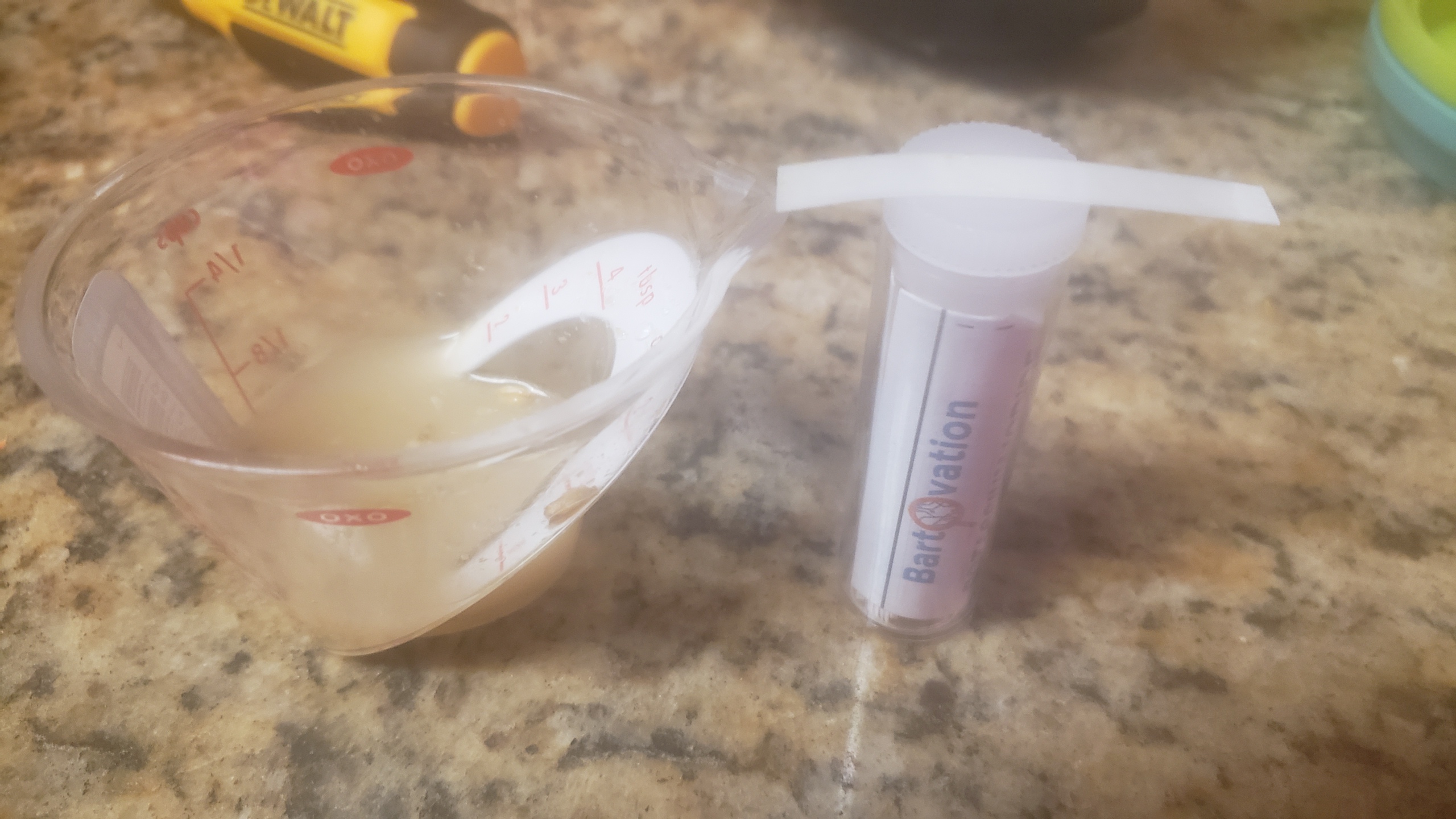

Dec 31: As the sun sets on the third day of the experiment, the starch test comes back negative

This is important; it means that rhyzopus has worked hard, and there's no free starch left, at least in the liquid. There might still be a little left in the solids, but can't be much. This is consistent with what I read on various forums/subreddits.

There must be a bit of sugar left somewhere, since it's still bubling. I tasted the liquid. It tastes boozy and surprisingly sour, no detectable sweetness. Reminds me of sour beer I make with lachancea yeast. No funky flavors; maybe making beer with solid fermentation using angel yeast is actually viable. Maybe i'll try it some day

Why is it sour though? Is there lactic acid? Why is there lactic acid? I didn't order no lactic acid. Well, as long as there's enough ABV, I don't really care

The smell is now much less intense; the fermentation must be slowing down

Jan 05: A couple days ago I've been making beer, and decided to test the starch test on mash water before saccharin conversion. To my surprize, it came back negative; I quickly realized my error - I was expecting the 'starch test' to be paper laced with iodine for detecting starch

As it turned out, it was paper laced with starch for detecting iodine

That's dumb. Why would anyone care if there's iodine? You can't make booze out of it

Ok, change of plan; I bought a bottle of iodine solution. First I tested it on half spoon of white wheat soaked in warm water; surely, there has to be starch there

Then I tested the fluid from the fermenter

As expected, iodine turned blue in wheat water, but stayed brown in the wash

Well, that's proper starch test

So, the conclusion is, even if there was starch in the fermenter on Dec 31, there certainly isn't any left now

There are still bubbles in the fermenter, so there must be some sugar the yeast is still working on; It doesn't taste sweet, so there shouldn't be much left, but with all the lactic acid it's hard to tell

I'll leave the yeast to it for at least another week

Jan 14: Fermentation seemed to have stopped, so I've done the stripping run today. Boil started at around 91.5 - 92C, so it looks like the wash was somewhere under 15% ABV. Not as good as with rice.

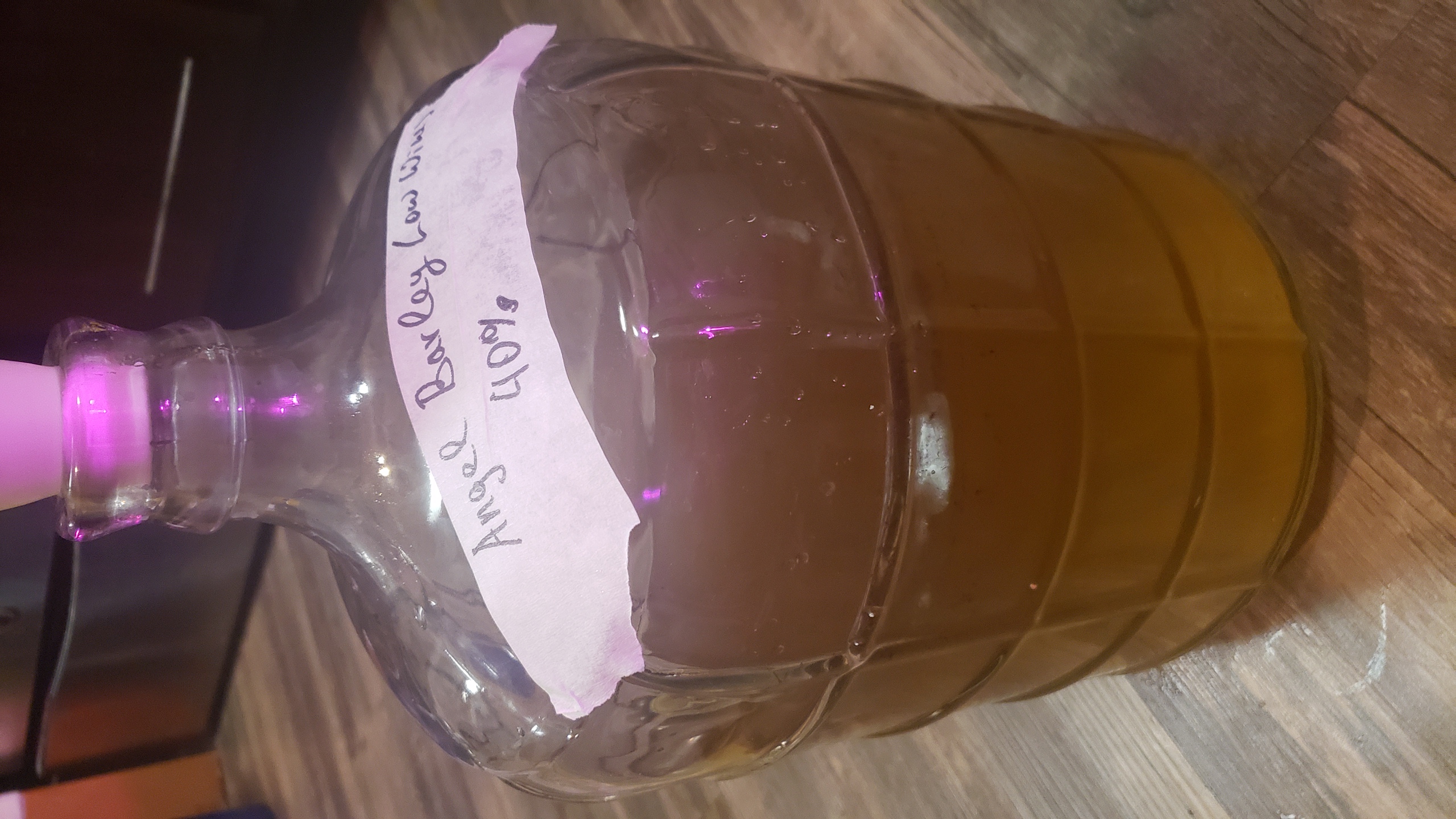

I got 7 liters (under 4 gallons) of low wines at 40% ABV. The liquid is a little murky, looks like it's been foaming. I thought of using some defoaming agent, but decided to try without it this time

The low wines taste rough, and the barley taste is really intense. Like, really, like you can't imagine. Wash smelled like vomit really funky sour beer, and tasted accordingly. The low wines smell and taste like fresh barley. Interesting

The liquid was brown-yellow at first, but changed color to more common moonshine white, with something like soot rising to the top

It's not soot, there was no burning at the bottom, but i guess it's some kind of fermentation byproduct

I'll do the spirit run next weekend; I want to recieve the flow regulator for the reflux column first

Also, I thought of infusing the low wines with botanicals and making it a gin, but the barley smell/taste is so intense I think it would be more fitting to make it a whiskey. I think I'll run it through the reflux and see how it turns out

Also, my conclusion is that, apparently, Angel yeast works with barley, but not as well as with rice; I think I'll try to perfect my rice game for now. I think rice gin will be the next project

I have thought pretty hard about what i want to do with this; I first thought of making whiskey, but then I thought, how about gin?

So, i made one more batch of rice wash, mixed the barley low wines, and did the stripping run. I didn't take any pictures, it's not very different from the angel rice project i did last time. Result still tastes like barley, but since we're doing gin it will be a 3 step distillation (4 for the barley, since it went through the stripping run with the rice wash), so i guess most of the barley flavor should be removed

Feb 13: So, today I refined the alcohol

I wanted to use my reflux column, but couldn't make it work; once kettle temperature reached 83C, it stopped growing, even though the heater was consuming 1500W the whole time.

(Update: I read the manual once again, and discovered that I confused celcius with farengheit. No surprise nothing came out. I'll do it right next time)

My only explaination is that the liquid from reflux column was pouring back into the kettle, cooling it

Reflux column temperature was 17C (top of the recommended range for the column). Then i increased it to 25C, and to 30C, still nothing came out

Anyway, I'll figure it out later. I used the alembic again

The result was ~8.2 liters of alcohol at 77% ABV. I watered it down to around 40% (though I tried to err on the side of higher abv, so it was probably 45%)

I didn't make proper cuts, but I did discard around 100g of foreshots; the first heads tasted ok, so they went straight into the result. then I just ran it up to 92C.

Then, the gin itself:

Alcohol: 15.4 L 40% +

Juniper: 112 g

Cumin: 30 g

Bitter Curacao Orange: 56 g

Coriander: 34 g

Hibiscus: 42 g

I feel this shouldn't be too far from optimal. I know i probably should have used more juniper, but the bag i had only had 112 grams, so i added a little more other stuff

I'll infuse it for a day and do the final spirit run tomorrow or a day after

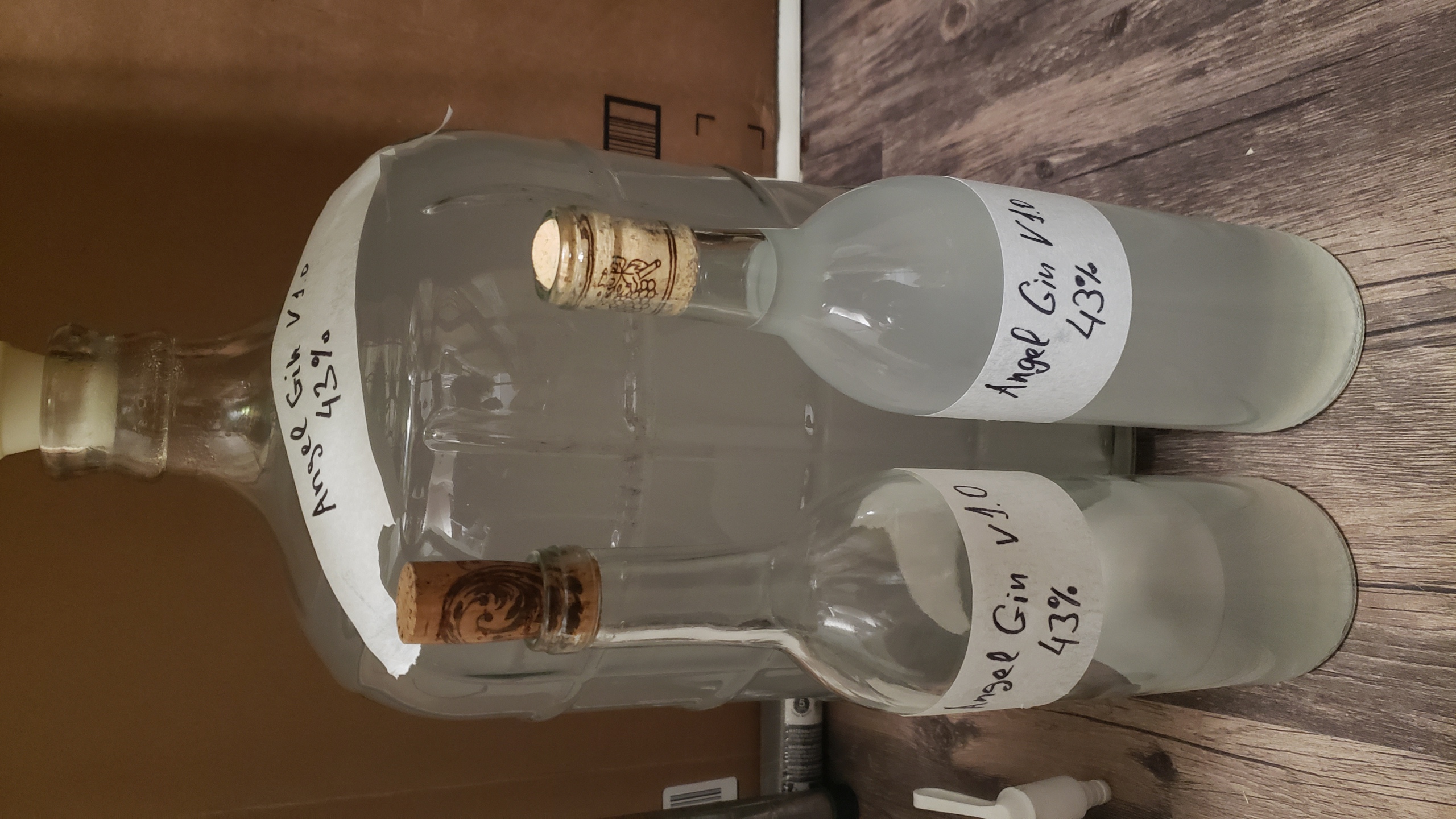

Feb 14: And done. I ran it through the still for the last time today. Now I have almost 4 gallons of gin

It is very opaque, much more so than any alcohol I made before

I knew it is very common with homemade gins; when it came out of the still, it was 75% ABV and completely clear. But, as i watered it down to 43%, the essential oils became no longer soluble, and it acquired a more traditional moonshine appearance.

How does it taste? Pretty pleasant, actually. All the refining paid off, so there's very little burn. The flavor is a little too cumin forward, but i still taste some juniper. Orange peels and hibiscus didn't seem to contribute that much

Since i have so much, I think I'll oak age a gallon, save another gallon jug, and bottle the rest

Cheers!