It's been a while since I tried making alcohol out of rice. My first two attempts to make rice wine were disasters; I ended up with a product that was sickeningly sweet, and had an aftertaste that was hard to describe; there must be some household cleaning product that tastes like that, but I can't think of it off the top of my head

Anyway, now I'm going to do things a little differently; If you know me, you must know that I'm a sucker for using unusual cultures in fermentation; Today I'm going to try something very new - Yellow Label Angel Yeast

According to the package, it's an unholy alliance of Rhizopus and yeast. Notice how it doesn't say Rhizopus oryzae? I suspect that's because it's not

The yeast is almost certainly Saccharomyces cerevisiae, probably of a distiller variety. That's good, I'll need strong yeast for what I'm planning

Now, time for preparations. First of all, I need a large bucket

This is a 20 gallon Baker's Mark bucket I got from a local homebrew shop (Beverage People in Santa Rosa CA). According to its specs, the temperature range goes all the way to 190F; I'd prefer 212, since I'm planning to pour boiling water into it at some point, but it will get mixed with room temperature rice, so it should be ok

Then, I need to decide how much stuff to add; The instructions on manufacturer's website were rather confusing (probably poorly translated from Mandarin), but I found better instructions here

According to these instructions, I managed to calculate how much stuff I can ferment in this bucket:

Rice: 40 lbs

Water: 14.5 gal

Angel yeast: 145 grams

That is going to fill up the bucket very nicely

Nov 19: The rice I ordered online has finally arrived

Have in mind that, even though for wine making you must use high gluten rice (like sushi rice in the picture), yellow label culture should be able to digest any kind of rice.. or actually any kind of anything, I read it can work with almost any grain; not sure about other starch sources, like potatoes, maybe I'll give it a try at some point

First, dump the rice into the bucket:

I've never seen so much rice at once in my life

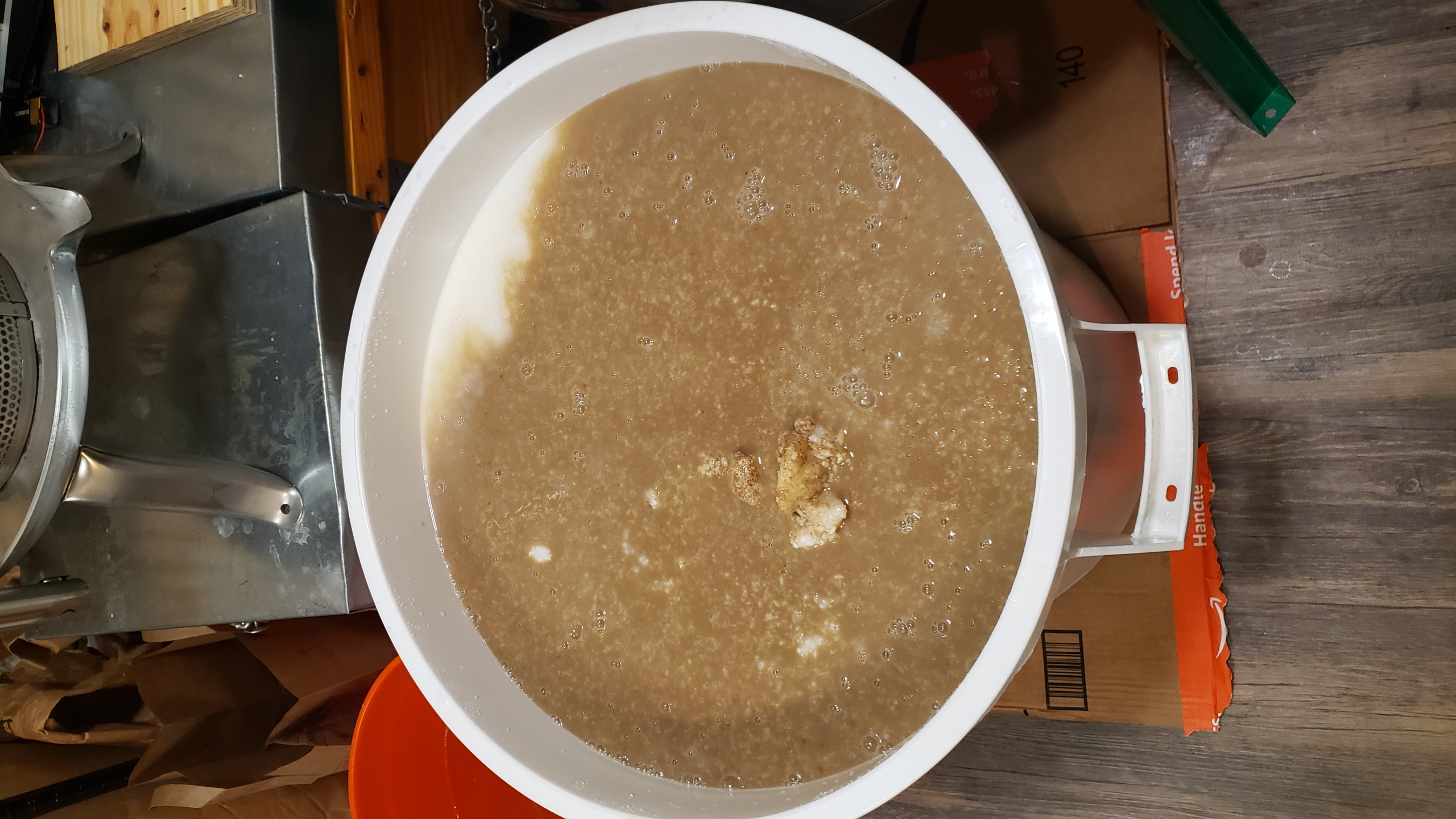

Then, add boiling temperature water. My largest pot only allows to boil 4 gallons at once, so I'll be adding 4 gallons at a time. I could boil more in my Grainfather beermaker, but it's occupied today (yes, I'm making a wheat sour at the same time)

That's pretty full. Then I decided to activate the yeast, since I couldn't wait. I scooped up half a jar of rice water from the bucket, and let it cool down; then added the yeast powder. Within a few minutes, I had a rather agressive activation on my hands

Then, I found that I grossly underestimated how long it would take 20 gallons of rice and water to cool down; last bit of water I added should have been cold. I'll do better next time.

Nov 20: Anyway, I had to leave the rice mash to cool overnight; when I woke up, it was still almost at 40C. Well, the yeast should survive, even though its ideal temperature is around 30

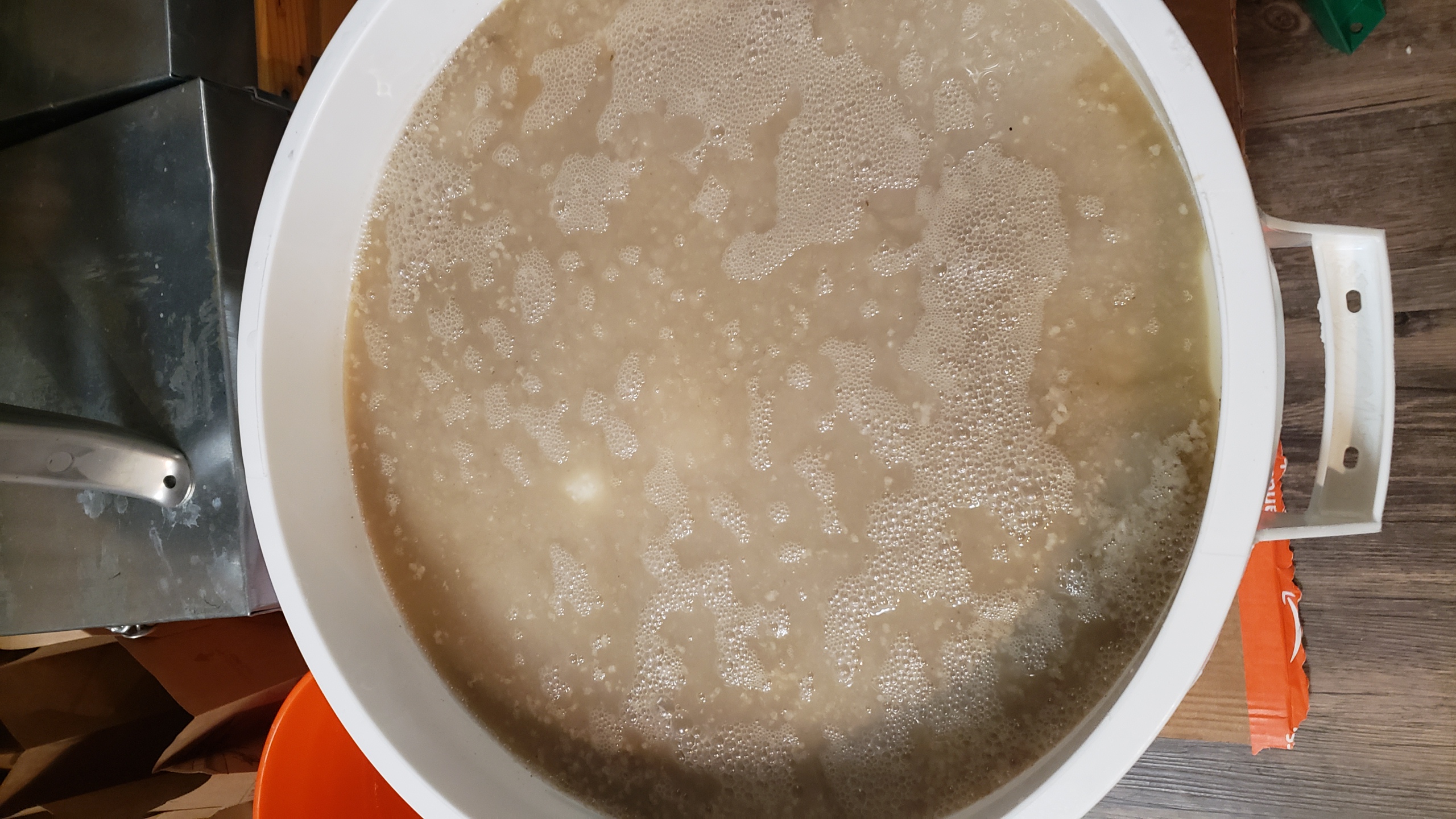

I added the yeast to a container of rice and water, to make sure the culture was still viable. Of course it was, it wouldn't die in just a few hours. It got nice and foamy real quick

I dumped the mix into the bucket and gave it a gentle stir

According to the instructions, I should have stirred very hard, but I wanted the yeast to stay at the surface for a while, in case the mash is much hotter closer to the bottom. Also, Rhizopus makes the rice less sticky, so it will be easier to stir once it's fermented a little further.

I kept the lid open for now, just to help it cool down. This yeast should be good with open fermentation

Then I went out for breakfast. As I got back an hour later, the bucket was actively bubbling (pretty loudly), and smelling like kimchi

According to what I have read, fermentation takes about 2 weeks, but that's at 30C; I don't have a heated fermenter, so at room temperature it will probably take a little longer

We'll see how it turns out

(By around noon I gave it a very vigorous stir, and measured the temperature; it was exactly 30C, so I closed the lid. I will keep regularly stirring it for the next few days)

2 PM: fermentation is accelerating

Unlike beer/wine fermentation I normally do, there's no Krausen (foam on top), even though there was a bit in the beginning. A lot of bubbles coming up, but not forming a foam

My appartment smells like rice and yeast; I guess I'll have to learn to live like this for a couple weeks

Nov 21: I've never seen a fermentation process so intense

The rice mash has thinned considerably; now instead of large bubbles you could see in the .gif image above, there's hundreds of tiny bubbles rising and popping every second. The fermenter is warm to touch. The smell is less overwhelming, and I'm beginning to smell alcohol

Per instructions, I keep giving the mash a vigorous stir twice a day.There are chunks of stuck together rice that I can't efficiently break down with my mixing spoon, but each time I stir they are smaller; the culture must be good at eating them away

Dec 18: Finally, the fermentation has stopped. Time to sample the product

This actually tastes like sake; maybe not the best sake, but I would drink it. A little murky, but can be clarified with enough patience. Great success. Much better than the sweet acetone I made in my previous attempts at rice wine. Now, to the next part

So, the hardest part is separating the liquid from the solid sediment; With rice wine you get much more sediment than with anything else, since, you know, solid fermentation.

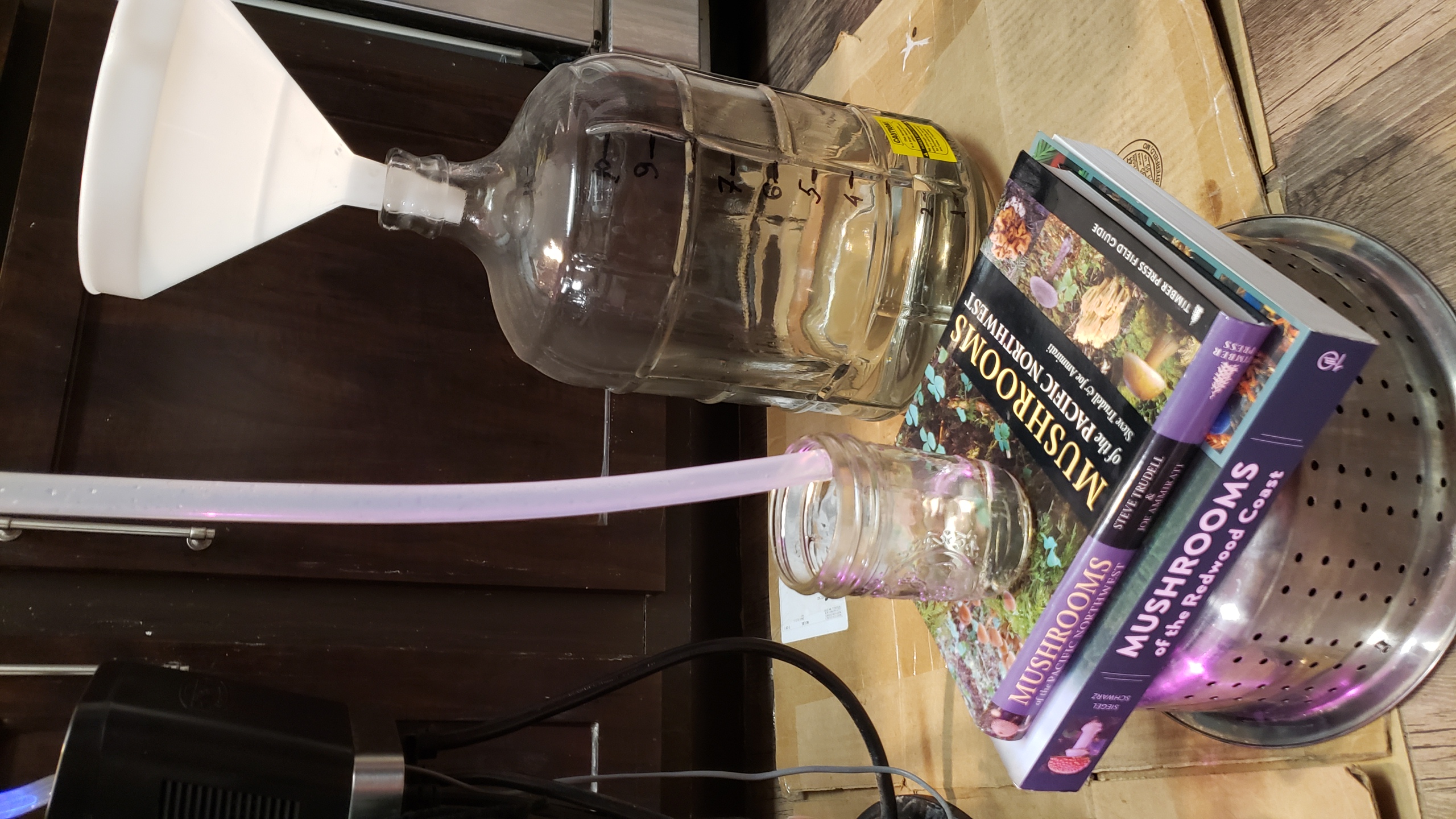

So, as you remember, 14.5 gallons of water went into the fermenter. I could syphon 8 gallons of wine off the top with relative ease

7 gallons went into the kettle; I could fit in a couple more, but I didn't want to make it too full. You never know if the thing starts foaming when you boil it

Nothing is floating in it, it's just a reflection

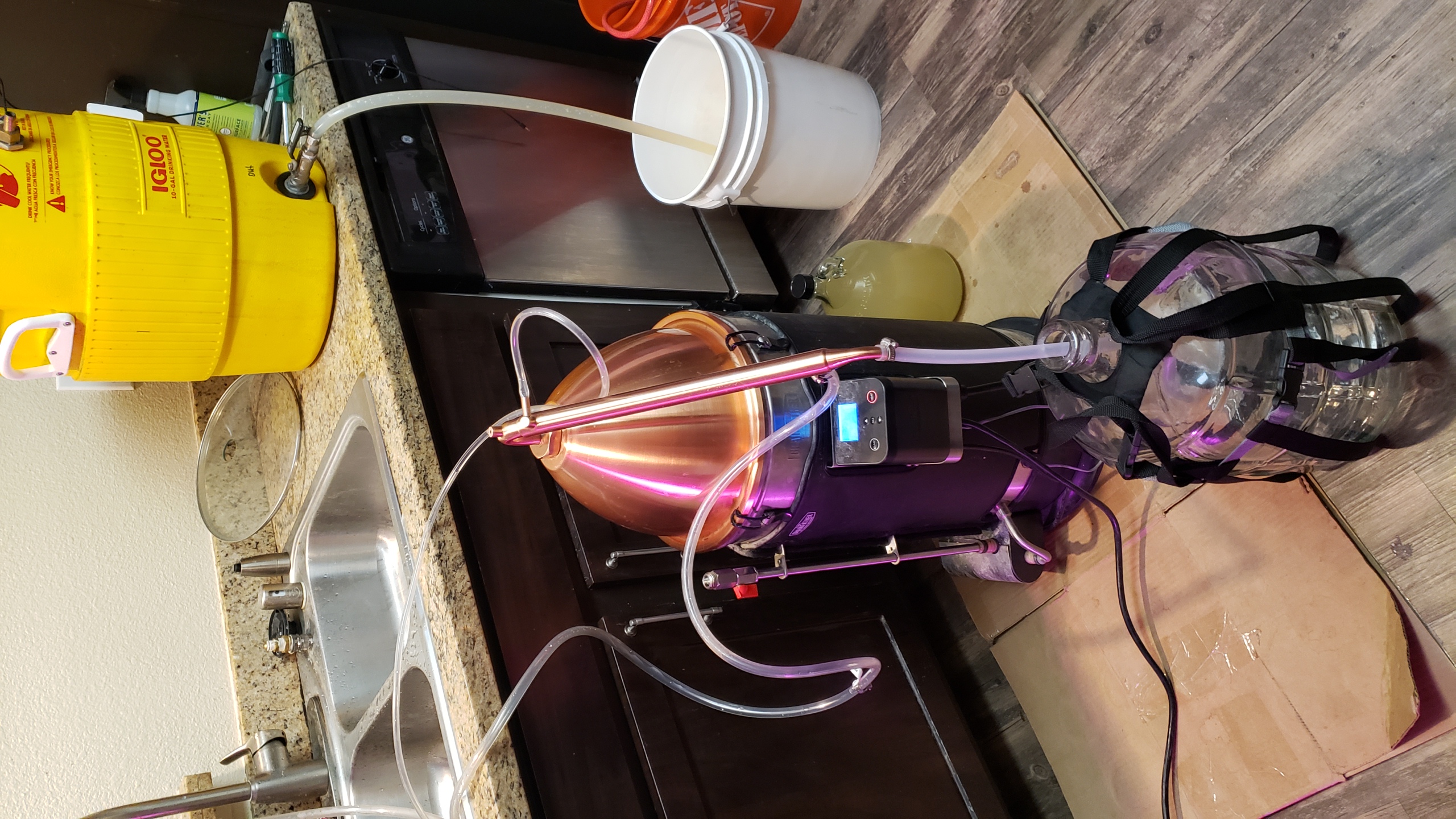

Time to get the alembic on and start the first stripping run

The yellow bucket you see in the back is for filtration. It has a false bottom wrapped in cheese cloth, and I run the rice sludge through it

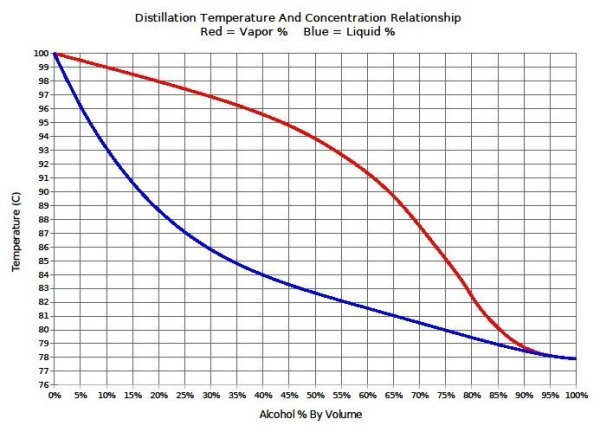

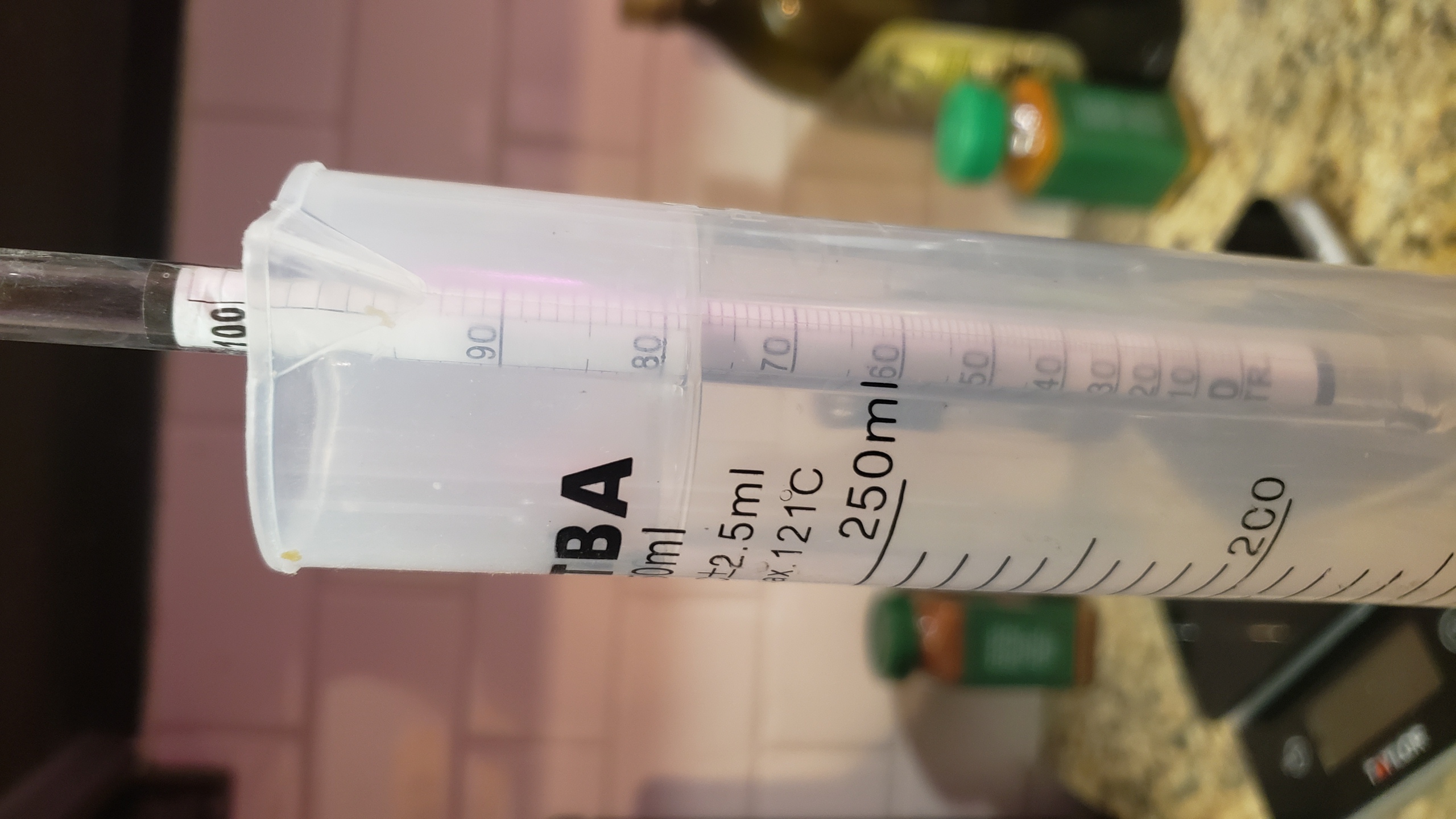

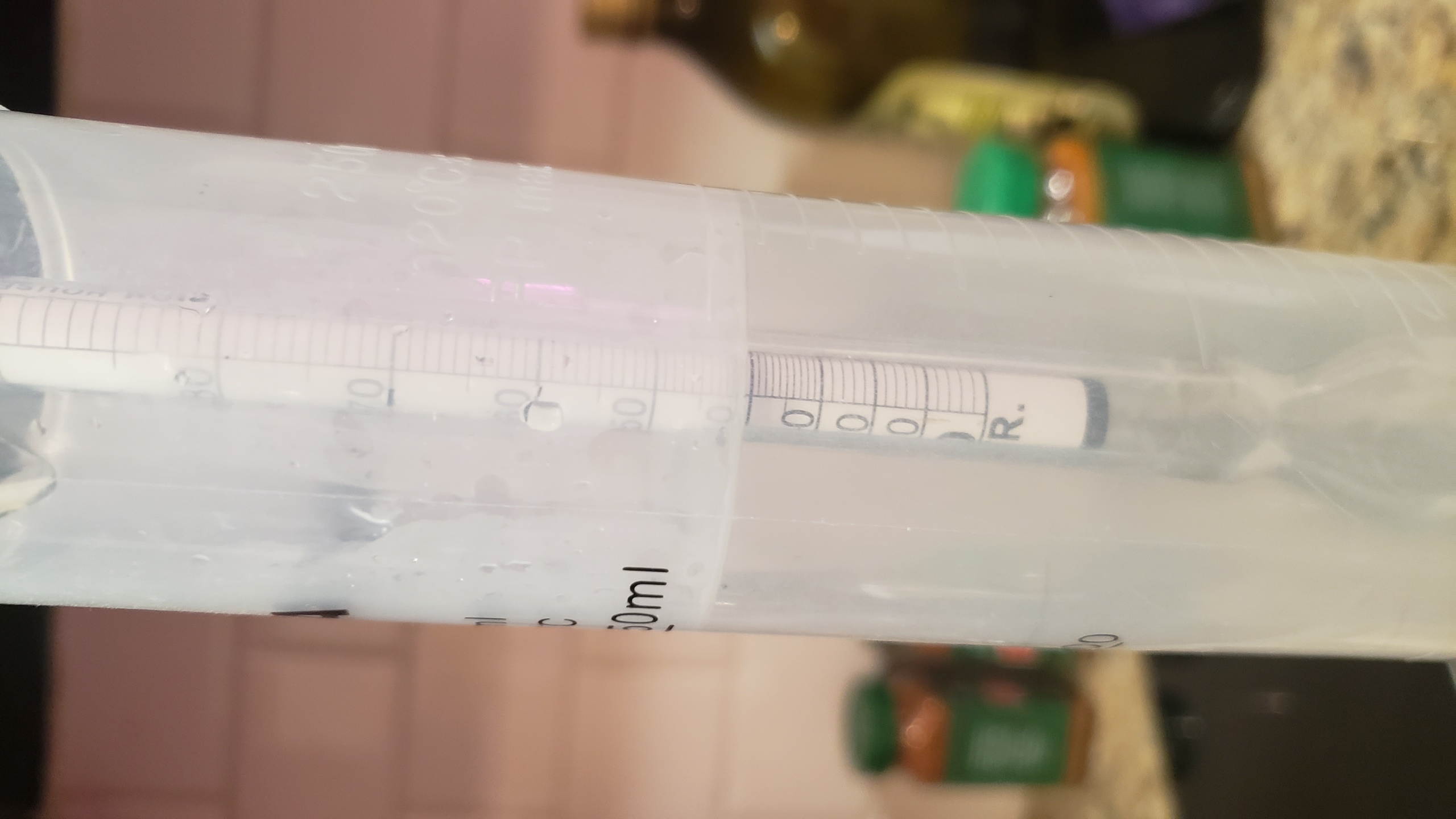

With solid fermentation it's really hard to tell how much alcohol there is in the wine; you can't take a gravity reading in the beginning, since all the sugars and starches are in liquid form. Fortunately, you can deduce it during distillation using the moonshine curves

I got a steady flow of vapor at 88°C; That means the wine was around 20% ABV. Pretty good.

First we need to do a stripping run: collect everything that comes out of the still up to 98°C. Since everything is crammed into a 10 degree range, it's really hard to make the cuts; We'll remove all the bad stuff, like methanol, aceton, ethanol acetate, and isopropyl when we run it through the still for the second time.

Now all we got to do is crank up the heat and watch the alcohol run.

While the wine is being distilled, I have done my best to filter 4 more gallons of wine out of the sludge. Couldn't squeeze any more. So, 11 gallons of poorly filtered wine total; not too bad. From what I learned, they don't filter out everything in Japan, what's left is used to make vinegar later. I don't feel like making vinegar today, maybe next time.

Now, I got the results of the first spirit run. This is called Low wines. Not ready for consumption yet

I got about 8 liters (a bit over 2 gallons) of low wines at 50% ABV. Acceptable

Then I added about 1/3 gallon of wine I saved from the beginning (this technique is called one and half distillation, it adds some flavor to the final product; it's fine to water down the low wines, as long as it stays above 40%)

Now, time to run this through the still for the second time. This time it's more work, since I had to sample every little batch, and made sure to remove everything that tasted like acetone (that part is called heads, and comes out in the beginning), or burned rubber (or tails, comes out closer to the end, flavor is from isopropyl)

Looks like during this run the seal between the kettle and alembic dome got a bit misaligned, since I saw a bit of vapor escaping on one side; but apparently I didn't lose the whole lot of alcohol this way. The grainfather's silicon parts are generally a lot of headache; I should probably glue it in with silicon glue before I use it next time

I started getting slightly rough flavors at around 90°C, and decided to cut off at exactly 91°C

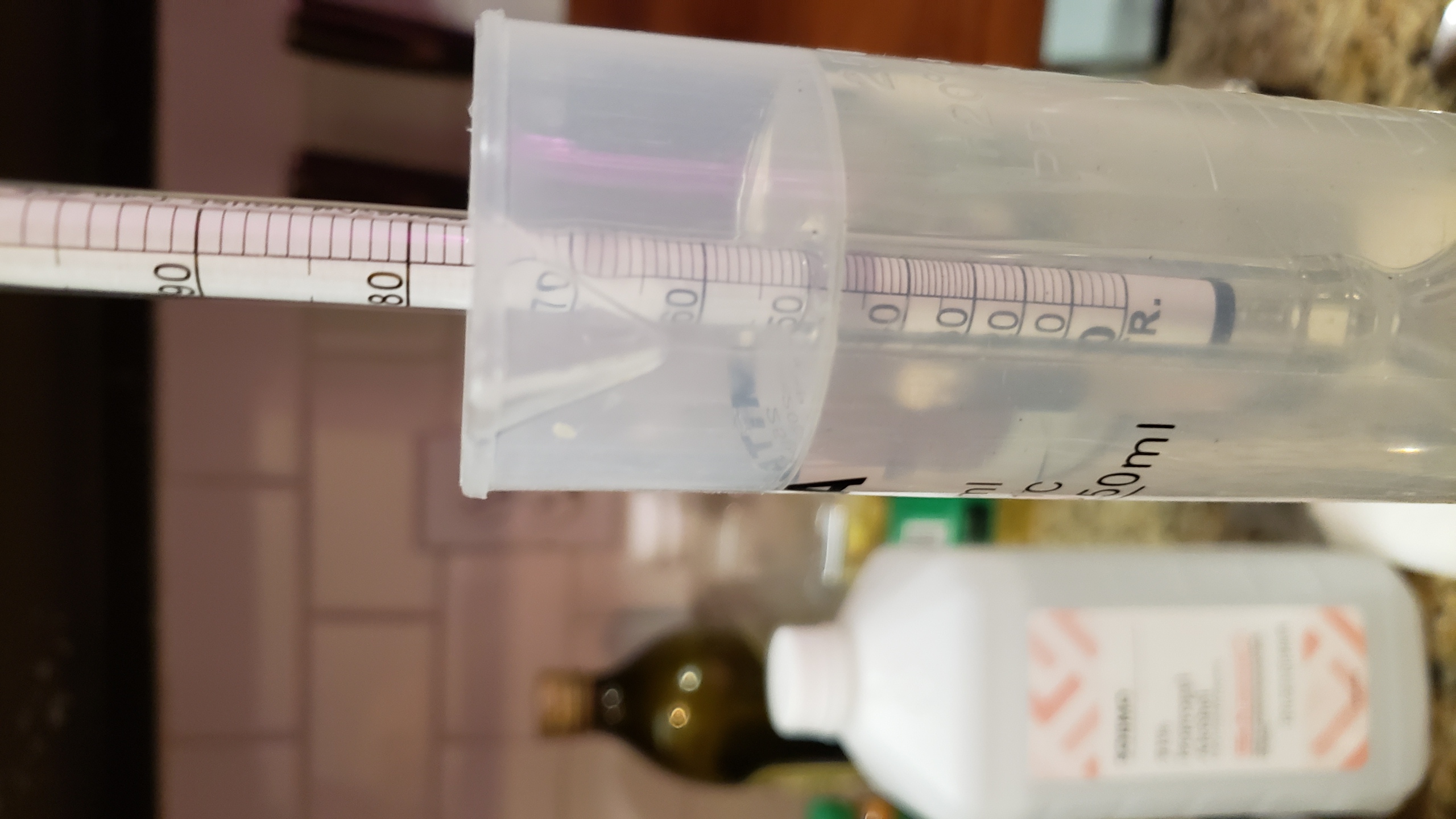

That gave me 4.75 liters (1.25 gallons) of end product at 78% ABV

Well, I can't offer people 78% moonshine; it's just rude. I decided to water it down to 42%.

that was just enough for 2 gallon jugs, 1 full wine bottle, and 1 incomplete wine bottle. Added a bit of an oak spiral into one of the gallon jugs; I know oak aged baiju is a thing, even though it's not extremely common

Looks like my work here is done!

Jan 10: Recently I mentioned to my Chinese friend that I made baiju; her reaction was 'great, does it taste like maitai?'

My first reaction was, of course not, maitai tastes like acetone, and I removed that during the spirit run. And then I thought, wait a minute, is real baiju supposed to taste like acetone?

So, I did some reading, and apparently baiju is made in a single run. Well, that explains a thing or two

Ok, so whatever I made is not baiju. What is it then? For now, working name is rice whiskey. Also, I keep getting good reviews from everyone who tries it.

Now, even though it is not baiju, I want to age the gallon I have without oak in a traditional Chinese way, in terracota vessels. I ordered 3 nice hand made clay jars online. They took a while to arrive, and then it was really hard to find corks of the right size, but now I finally got everything.

Here are the jars I used

The product description did not mention the neck diameter, but it's 1.3 inches; #16 corks seem to be the best fit

The necks aren't perfectly round so the corks won't fit in perfectly, but fortunately I have a lot of beeswax, so I'm using it to seal up the jars

And, after a bit of work with a heat gun, it's done

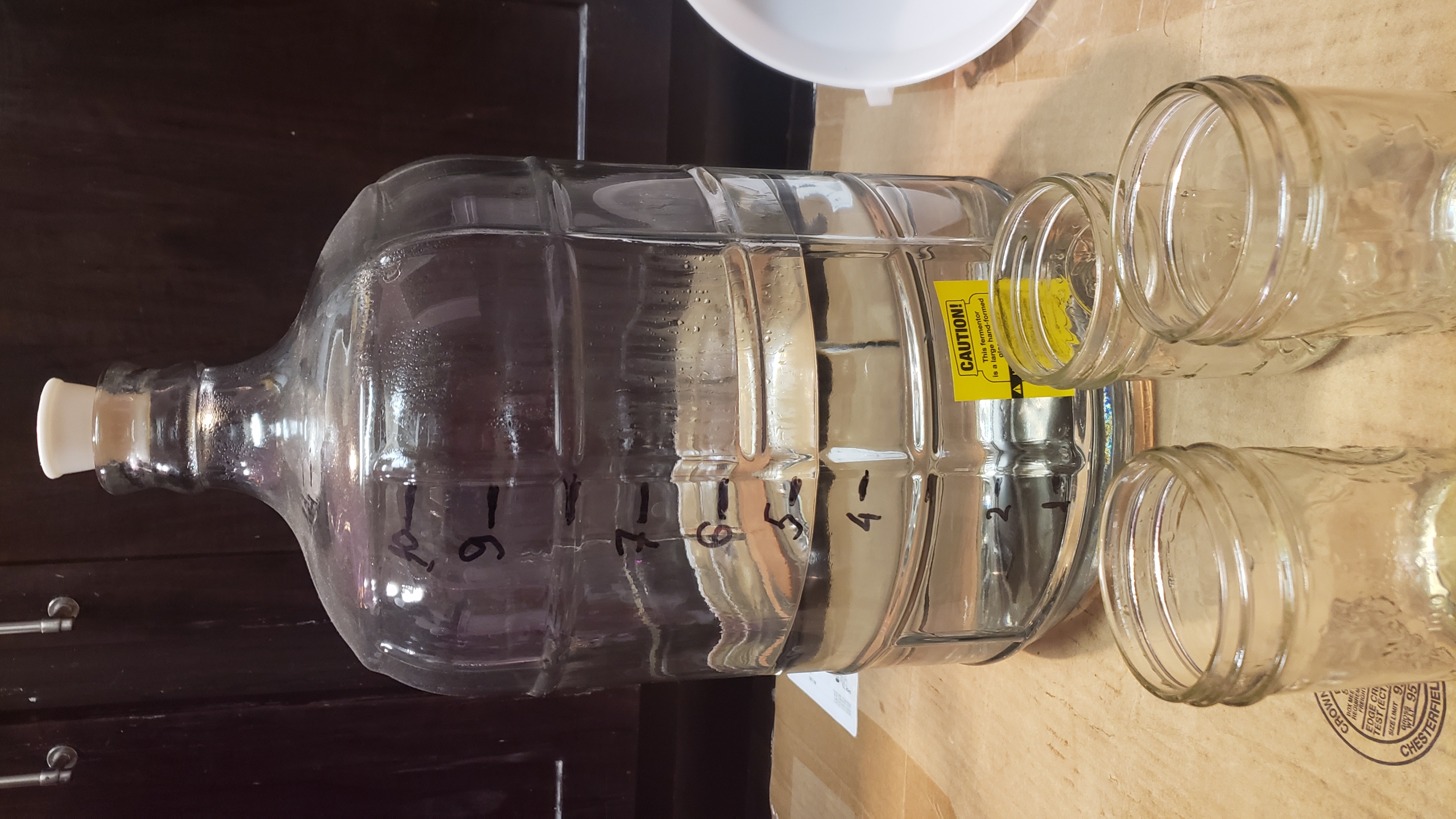

Jan 11: Terracotta jars turned out to have been a bad idea. I've never had to deal with terracotta before, so I had no idea just how porous it is. Liquid seems to be leaking through the walls; At this pace, in a month most of it will be gone. I don't know how they age baiju in terracotta in China, but it's probably some special kind of terracotta. Anyway, I've unsealed the jars and poured the moonshine back into the glass carboy